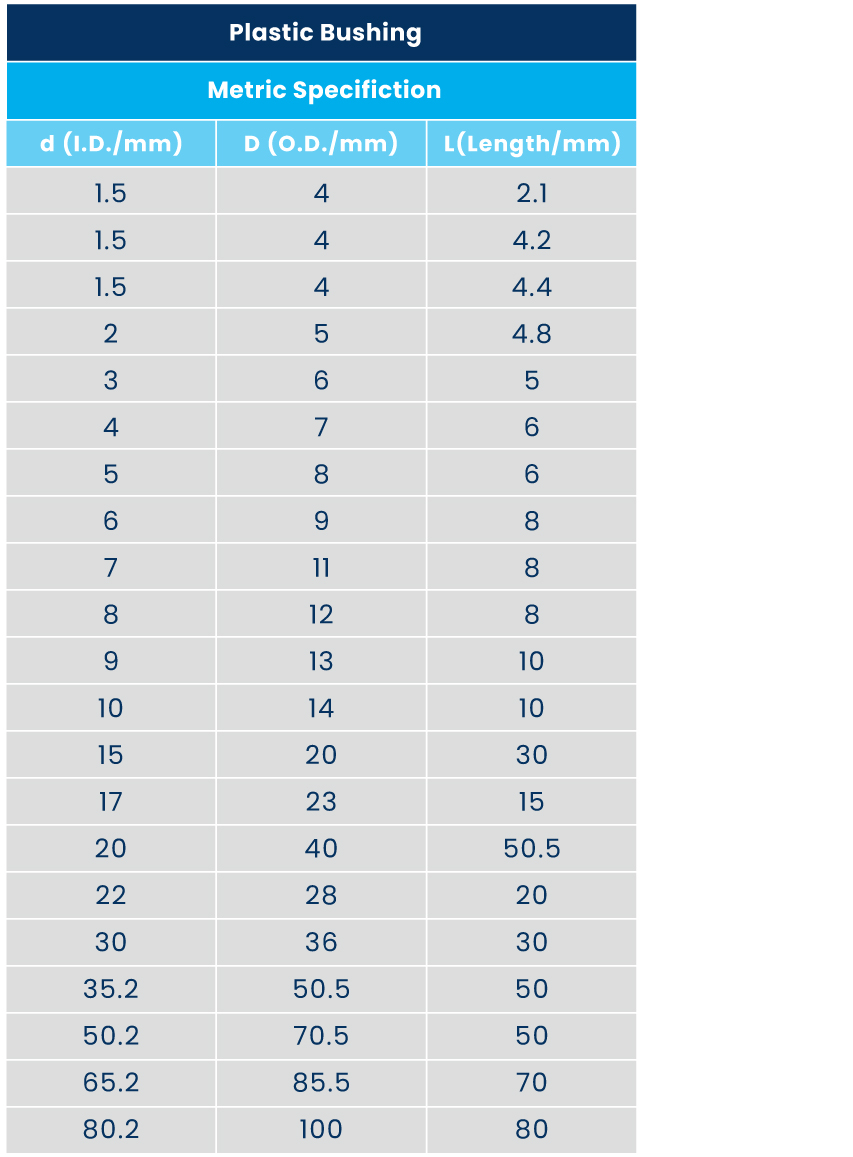

Plastic Bushing

Material Selection :

PEEK (Long-term use temperature 240℃) :

PEEK is a semi-crystalline engineering plastic, suitable for applications that used in high temperature, chemical solvent process. PEEK material is tough, rigid, creep-resistant, light-resistant, and multi-ray resistant. Screws, nuts, and various spare parts made of this material are widely used in semiconductor equipment, aerospace vehicle industry, automotive electronics and motor industry, oil/gas extraction equipment and even medical equipment or food production equipment.

PPS (Long-term use temperature 200℃) :

PPS is a thermoplastic special engineering plastic, featuring high temperature resistance, corrosion resistance and high mechanical strength. In addition, it has electrical properties and dimensional stability which allows PPS-made parts suitable for electronic and electrical parts, auto parts, and chemical machinery parts.

PVDF (Long-term use temperature 150℃) :

PVDF is a thermoplastic fluoropolymer with excellent chemical resistance, weather resistance, high temperature resistance, electrical insulation, lubrication, and wear resistance; it is suitable for various environments of acid-base solvent, semiconductor manufacturing processes, wet chemical processes, and equipment parts in the chemical industry.

PP (Long-term use temperature 90℃) :

PP features excellent stretchability, chemical resistance, hydrolysis resistance, electrical properties, and is suitable for use in various chemical environments, food production equipment and pharmaceutical machinery parts.

PTFE (Long-term use temperature -190~260℃) :

PTFE is one of the fluorine-based resins, which is resistant to most chemicals and solvents. Due to excellent electrical properties, non-stick and lubricity, it is widely used in high temperature, chemical, electrical, mechanical and aviation fields.

NYLON (Long-term use temperature 70℃) :

Nylon plastic has heat resistance, high hardness, wear resistance, and low friction coefficient; it is suitable for parts in mechanical engineering, food technology, electronics aviation, aerospace technology, and automotive industry.

TPI Self-lubricating (Long-term use temperature -269~280℃) :

TPI has excellent high-temperature resistant, wear resistance and friction performance under high pressure and high-speed scraping. Low gas performance under high vacuum state, excellent chemical resistance and mechanical properties, extraordinary dimensional stability, and low electrical conductivity.

POM (Long-term use temperature 100℃) :

Also known as plastic steel with high rigidity, low friction, and dimensional stability. Resistant to most chemical solvents (non-acidic) and oils.