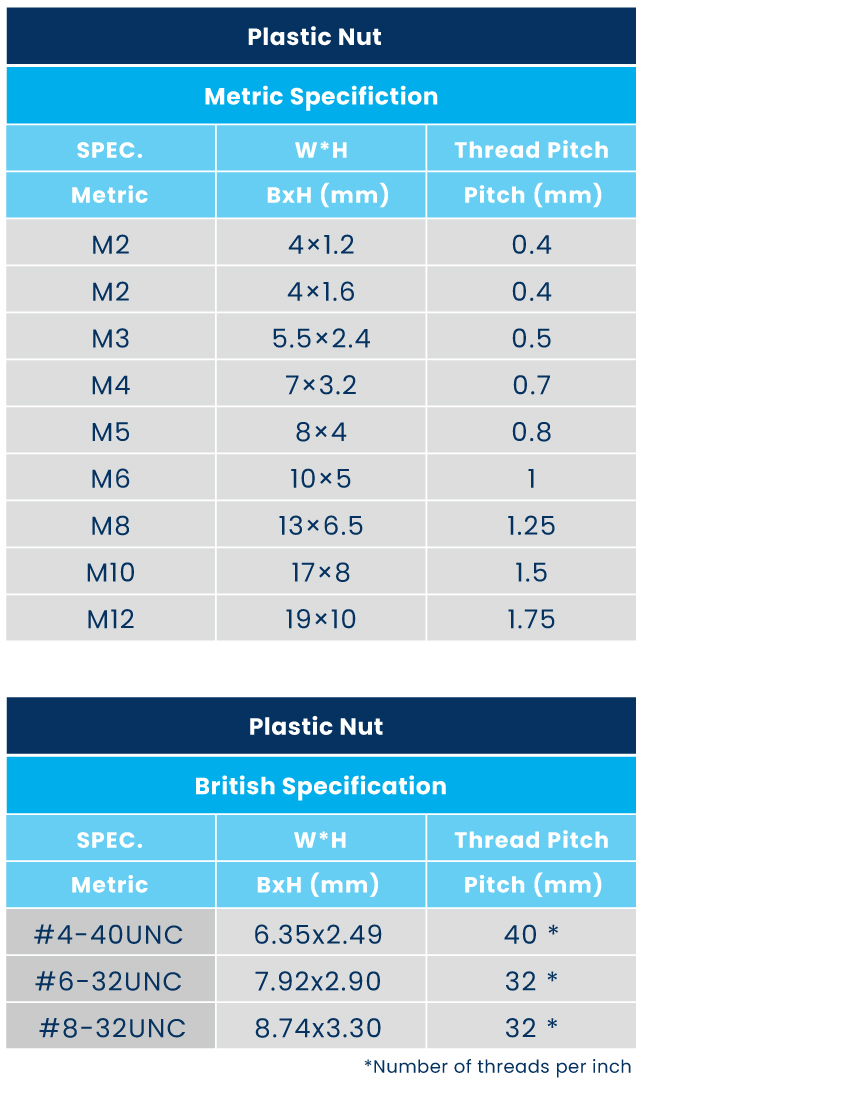

Plastic Nut

A complete range of plastic screws, bolts, nuts, sizes from M1.4 to M16.

Complete styles of screw heads are available for various equipment design requirements.

Material Selection:Various materials are available for selection according to different environments and temperature requirements.

PEEK (Long-term use temperature 240℃) :

PEEK is a semi-crystalline engineering plastic, suitable for applications that used in high temperature, chemical solvent process. PEEK material is tough, rigid, creep-resistant, light-resistant, and multi-ray resistant. Screws, nuts, and various spare parts made of this material are widely used in semiconductor equipment, aerospace vehicle industry, automotive electronics and motor industry, oil/gas extraction equipment and even medical equipment or food production equipment.

PPS (Long-term use temperature 200℃) :

PPS is a thermoplastic special engineering plastic, featuring high temperature resistance, corrosion resistance and high mechanical strength. In addition, it has electrical properties and dimensional stability which allows PPS-made parts suitable for electronic and electrical parts, auto parts, and chemical machinery parts.

PVDF (Long-term use temperature 150℃) :

PVDF is a thermoplastic fluoropolymer with excellent chemical resistance, weather resistance, high temperature resistance, electrical insulation, lubrication, and wear resistance; it is suitable for various environments of acid-base solvent, semiconductor manufacturing processes, wet chemical processes, and equipment parts in the chemical industry.

PP (Long-term use temperature 90℃) :

PP features excellent stretch ability, chemical resistance, hydrolysis resistance, electrical properties, and is suitable for use in various chemical environments, food production equipment and pharmaceutical machinery parts.

PPGF (Long-term use temperature 120℃) :

PPGF is PP with glass fiber added to increase strength, has excellent chemical resistance, high purity, low water absorption and good electrical insulation properties and high temperature resistance.

PPS+GF (Long-term use temperature 240℃) :

PPS added with glass fiber to reinforce strength and temperature resistance and has corrosion resistance and high mechanical properties, most importantly PPS's properties get no degradation after long-term use in high temperature environments. In addition, it has electrical properties and dimensional stability, and is suitable for applications such as electronic and electrical parts, auto parts, and chemical machinery parts.

RENY (Long-term use temperature 105℃) :

High-temperature resistant nylon engineering plastics are added with glass fiber to increase strength, excellent oil resistance and high-temperature resistance, and parts made by RENY are widely used in automobiles, machinery, precision mechanical parts, electrical and electronic equipment, as well as civil engineering and construction materials.

PVC (Long-term use temperature 60℃) :

PVC is resistant to acid and alkali, has excellent electrical insulation, high mechanical strength, and good weather resistance. PVC is often used in mechanical components in contact with chemical solvents or outdoor equipment parts such as building materials, packaging, medicine, wires, and cables.

TPI (Long-term use temperature -269~280℃) :

TPI has excellent high-temperature resistant, wear resistance and friction performance under high pressure and high-speed scraping. Low gas performance under high vacuum state, excellent chemical resistance and mechanical properties, extraordinary dimensional stability, and low electrical conductivity.

PTFE (Long-term use temperature -190~260℃) :

PTFE is one of the fluorine-based resins, which is resistant to most chemicals and solvents. Due to excellent electrical properties, non-stick and lubricity, it is widely used in high temperature, chemical, electrical, mechanical and aviation fields.

PCTFE (Long-term use temperature -200~200℃) :

PCTFE is a fluoropolymer, low/high temperature resistant, chemical resistant, low permeability, and weather resistant. Widely used in semiconductor process equipment parts.

PEEK+GF (Long-term use temperature 260℃) :

PEEK engineering plastics can withstand high temperature up to 260°C, and are suitable for thermal performance, chemical performance, and flame resistance (V-0); adding glass fiber improves its rigidity and higher temperature resistance.

PFA (Long-term use temperature 260℃) :

PFA has low/high temperature resistance (-200°C~260°C), chemical resistance, weather resistance, and excellent mechanical strength. It is widely used in pharmaceutical equipment or semiconductor wet process equipment related parts.

NYLON (Long-term use temperature 70℃) :

Nylon plastic has heat resistance, high hardness, wear resistance, and low friction coefficient; it is suitable for parts in mechanical engineering, food technology, electronics aviation, aerospace technology, and automotive industry.